![]() Ця сторінка також доступна українською.

Ця сторінка також доступна українською.

Introduction

The pink sandstone headstone of Velvet Gaba, died 5732 on the Hebrew calendar (1931-1932). The burial marker was repurposed after the war as a grinding stone, then returned anonymously in 2020 to the old Jewish cemetery in Rohatyn (Ivano-Frankivsk oblast). Photos © RJH.

More than any other discipline relevant to cemetery preservation, stone conservation is a specialist field which requires study, hands-on training, and experience to be effective and to minimize harm to existing heritage. Project leads and activists who aim to repair and protect the headstones and other historical stone features which have survived at cemeteries in their care should work under the guidance of established experts, or should leave this work to others who have the necessary knowledge and skills. The information presented on this page is best considered as an introduction only, although we attempt to provide a range of useful information in a practical format for planning and for background study. Heritage activists who are approaching their first headstone projects should especially review the cautions and considerations in the last section of this page, which includes notes on “what not to do” with stone in cemeteries.

Several stone conservation issues on display in the Jewish cemetery of Rozhniativ

(Ivano-Frankivsk oblast). Photo © RJH.

Stone conservation is an increasingly active global academic discipline; the published literature demonstrates both significant advances in the past few decades as well as the considerable uncertainty which still dominates several critical areas of study. The references page for stone conservation on this website includes links to many practical and specific resources in book, article, web page, and video formats; a data page on this website also describes and tabulates selected physical properties of the most common stone materials found in Jewish cemeteries in western Ukraine.

Key information resources are provided freely by government and private conservation organizations, in particular the US National Center for Preservation Technology and Training (NCPTT) and the Getty Conservation Institute (GCI) – both of which also offer periodic hands-on training courses in heritage stone conservation (in the US and Italy, respectively). The detailed GCI overview of current research in stone conservation (2010; see the references page) is an excellent entry point for study in the field, and NCPTT videos are helpful visual demonstrations of many key tasks. Practical training and experience is also provided every year by Stowarzyszenie Magurycz, a small Polish NGO which conducts cemetery marker restoration work camps primarily in eastern Poland and western Ukraine, on stone issues found at Christian and Jewish burial sites which are now detached from their original regional religious communities. For activists who wish to gain a solid academic foundation in the discipline, strong theoretical and practical teaching programs in stone conservation are also available at select universities, especially Lviv Polytechnic National University and the University of Pennsylvania’s Center for Architectural Conservation.

Controlling vegetation and water are probably the priorities for protecting headstones in the

Jewish cemetery of Solotvyn (Ivano-Frankivsk oblast). Photo © RJH.

In the sections below, brief mention is made of headstone recovery and documentation, with more detailed discussion on the evaluation, cleaning, treatment, repair, and resetting of headstones. As noted above, most categories of stone care are difficult to cover adequately on a webpage, so supplemental notes are included here about specific misunderstandings and errors to avoid while a comprehensive project stone conservation strategy is not yet defined. It is important to recognize that apart from the sudden catastrophe of the Holocaust and the sometimes wholesale destruction during the Soviet era, weathering and other deterioration of stone markers and monuments in Jewish cemeteries is normally a natural and very gradual process: there is rarely reason for alarm and urgent action upon the stones themselves. Vegetation trimming and management plus occasional intervention to minimize accidental damage will usually take priority over headstone repairs, resetting, and even cleaning, especially if volunteers and leaders are unsure about safe tools, materials, and methods to clean and protect valuable stone heritage. Waiting another year to learn and ask advice is often the most prudent approach.

Recovering Displaced Headstones

Jewish headstone fragments gathered by local residents of Sokolivka (Lviv oblast) and returned by ESJF

to the Jewish cemetery in the village. Photo © RJH.

This website aims to provide guidance and information on the discovery, assessment, care, memorializing, and marking of Jewish burial sites in western Ukraine, including the headstones which Jewish cemeteries in the region sometimes contain (but often do not); thus this web project is primarily focused on the burial sites themselves. Recovering headstones which were displaced from Jewish cemeteries during or after World War II is not intentionally a defined phase in most project plans, but typically arises as an unplanned and improvised companion task to the site work, adapted in response to the highly variable specific circumstances of the original stone theft and the recent discovery. While this website cannot provide in-depth advice on headstone recovery, some guidance can be learned from a review of example past projects in the region, including case study 07 (ongoing, long-term), case study 13 (impromptu, short-term), and case study 11 (which includes headstone resetting). Additional and very specific practical advice is also available on the resources page on tools for recovering and transporting displaced headstones.

Evaluating the Physical Condition of Headstones

In Rozhniativ, the natural stone is proving more durable than the concrete meant to support it. Photo © RJH.

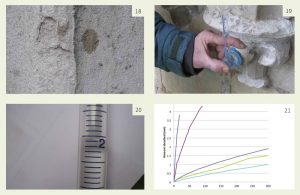

Before preparing a stone conservation and management plan for one or more headstones or a cemetery collection, the materials from which the headstones were cut should be identified and the physical condition of each stone should be evaluated. It is important to document any headstone to be treated by location in the cemetery or other ID both before and after the treatment, as a measure of the effectiveness of the treatment (and in case of initial misjudgment which leads to damage to the stone). See the section below on documenting headstones for information and recommendations.

Determining the specific types, compositions, and quarry origins of headstones is technically difficult and usually involves laboratory-based destructive testing and analysis, but that is not always necessary ahead of normal conservation work to clean, protect, and repair stone heritage in Jewish cemeteries. In many cases it is sufficient to identify the basic stone material class of a headstone and field-test the integrity of its body and surfaces through non-destructive or micro-destructive evaluations in a cemetery or at a recovery location.

Identifying the basic stone material: The simplest and most reliable way to identify the basic material classification of a headstone is to ask a professional – a conservation specialist, a stonemason, or a commercial stone supplier. These experts have both the training and the experience to assign stone examples into categories by composition, appearance, and functional characteristics. With guidance in the field from these experts, heritage project volunteers can themselves learn to recognize subtle visual qualities of the most common stone categories found in Jewish cemeteries in western Ukraine by eye and with optical magnification (e.g. a loupe or handheld microscope):

-

Using a USB microscope to identify, analyze, and document the stone type, lettering, and paint material on a Jewish headstone at the Bagnówka Jewish cemetery in Białystok, Poland.

Photo © Heidi M. Szpek.limestone: usually light to medium grey color, sometimes buff to tan; relatively fine-textured, with some veining; close inspection may reveal granules of shells and/or bones, or the impressions of fossilized marine animals

- sandstone: a wide range of colors including a soft pink favored in the region; relatively fine-grained without significant veining but sometimes with visible bedding and lamination layers

- granite: may be grey to pink, often with white and black grains plus reflective mica flecks; very coarse-textured with large grains; relatively scratch-resistant

- marble: a wide variety of colors; very fine-textured, often with prominent veining

Visual inspection and inventory: In addition to material identification, other visual features of a headstone and its physical condition should be briefly noted and recorded, formally or informally. Example features to inspect and record include:

- body position, size, and orientation: location; dimensions; attitude; compass orientation; uniformity; integrality

- stone carving and lettering: body shape; molding; incising dimensions and depth; relief dimensions and depth

- damage and/or deterioration: presence, dimensions, and types of: stains; chemical discoloration; smoke, soot, and other particles; crusts; chips, holes; cracks; crumbling; biological organisms; past repairs

Many of these aspects of headstone condition can be recorded with a camera, a tape measure, and a simple pre-printed form; the survey guide page and its references page on this website provide resources and examples. Observation notes may benefit from using standardized terminology from the EwaGlos European Illustrated Glossary of Conservation Terms linked on the stone conservation references page; the terms are in English with translation to 10 other European languages (not including Ukrainian, but the terms can be translated using the illustrations as a guide). As noted, the documentation section further down on this page also details guidance and examples on the recording of the cultural content of Jewish headstones.

Lichens and mosses on Jewish headstones in Solotvyn (Ivano-Frankivsk oblast) grow slowly but can cause pitting and disfigure carved epitaphs and symbols. Photo © RJH.

Acid sensitivity testing: To help confirm basic stone material categories and as a pretest before commencing cleaning and other treatment of headstones, an acid sensitivity test may be performed on a small and inconspicuous part of a headstone or fragment under study. This test involves mild acids which can harm people and stone; protection and care are needed for both. An acid diluted to about 10% in water composed of acetic acid (colorless unflavored vinegar) or hydrochloric acid (also called muriatic acid) is applied using an eye dropper. Place a few drops of the acid solution on an area of stone about 25mm diameter and observe the reaction. Calcareous stone (limestone or marble) will bubble or fizz noticeably as the acid attacks the calcium carbonate grains. Siliceous stone (sandstone or granite) will show little or no reaction to the acid. When the stone response has been identified, the test site should be rinsed thoroughly with clear water to remove the acid and any reaction products.

Surface integrity evaluation: Strength testing of natural stone typically focuses on stone as an architectural material, i.e. under structural loads. As headstones normally need to support only their own weight, any significant cracks and hidden internal defects can normally be evaluated simply by pushing on an upright stone or by lifting one end of a recovered stone or large fragment. However, loss of strength and integrity of the surfaces of headstones, typically from weathering, impacts the legibility of inscriptions and the useful life of the stone as a memorial object. Evaluation of surface integrity through inspection and testing should be performed before cleaning, consolidation, and any repair work, in order avoid damaging the stone during care. Some of the tests are equally applicable after surface treatments, to determine the degree of improvement.

Simple water absorption tests to assess stone porosity and decay employ a pipette and a Karsten tube. Source: Historic England.

A number of nondestructive evaluation methods for laboratory and field application have been described and compared in several references on stone conservation listed on this website. A helpful overview of methods with a detailed bibliography is provided by the Swedish National Testing and Research Institute. Relatively technical (and expensive) methods employ transducers working with radar, acoustics and vibration, ultrasonics, and/or infrared thermal imagery; some of the methods involve gently striking the stone to stimulate a mechanical response. An intermediate-cost instrument for field use is the Schmidt hammer, which is described in some of the references. A good introduction to four simple and inexpensive methods (water drop test, resonance pointer, brush test, and strip test) which may be used onsite in cemeteries was presented at the 12th International Congress on the Deterioration and Conservation of Stone in 2012. For each test type it is recommended to gain experience by testing known sound stone faces of similar materials, and/or the back sides of headstones, before evaluating carved feature surfaces which may be unsound. Although these tests provide some quantitative and qualitative measures of stone surface integrity, with practice it may be sufficient to use one’s bare fingers to inspect and qualitatively evaluate areas on headstones which appear decayed and/or loose.

Preventive Conservation Measures

Protective canopies over ancient stone sculptures at the Museum of Ukrainian History in Kyiv. Photo © RJH.

As noted in the introduction, active stone conservation measures are not advised unless performed by trained people who are skilled and experienced in the work, with knowledge of the characteristics of local stone varieties and the decay issues specific to heritage stone in Jewish cemeteries in western Ukraine. For many cemetery projects, indirect preventive conservation may be all that are practical and safe in caring for surviving headstones, though reducing the environmental stresses on headstones is an important initial step in any conservation plan anyway. However, these preventive measures will almost always be significantly constrained by practical, economic, and visual concerns.

As open-air sites exposed to extremes of environmental temperature and humidity, with natural stone markers historically embedded in earth and subject to atmospheric and subsurface moisture, wind, and soil chemistry, cemeteries and their headstones are and always have been man-made memorial features destined to decay over time. Preventive conservation measures applicable to stone buildings, even their exterior facades, are seldom suited to cemeteries. However, awareness of the dominant factors influencing stone decay rates can suggest selective site modifications which may slow the degradation of individual headstones or an entire cemetery.

Closed and open ohels plus a number of uncovered headstones in the old Jewish cemetery in Rohatyn (Ivano-Frankivsk oblast). Photo © RJH.

Water in all of its states and from several sources is a leading contributor to natural stone decay at Jewish burial sites. From above, rainfall wets and can saturate a headstone via all exposed faces, especially the top, and there is little which can be done about this without excessively altering the visual appearance of a stone and a cemetery. Canopies erected over significant historical pieces, such as over ancient carved stone artifacts outside the Museum of Ukrainian History in Kyiv shown here can reduce the amount of rainfall directly striking a stone, at least in part, but are visually distracting and impossible to implement for more than one or a few headstones in a cemetery. Ohels which cover the graves of prominent historical religious teachers in Jewish cemeteries may sometimes provide this limited form of protection, at potentially significant cost and adding new maintenance requirements. Canopies may also reduce other water-related stresses, for example by slowing the evaporation of water from saturated headstones exposed to sunlight, giving more time for soluble salts to migrate to the stone surface and thus limiting subsurface fractures. However, the required size of a canopy to significantly diminish each of these factors will rarely be considered befitting in a cemetery for more than a small number of headstones – if any.

Freeze-thaw damage to a recovered headstone fragment in the old Jewish cemetery of Rohatyn. Photo © RJH.

From below, water is absorbed by a headstone embedded in soil saturated by rainfall or snowmelt, a process which began when the stone was first erected decades or centuries ago. While it seems inappropriate to interfere with this “traditional” mode of decay, excessive standing water and especially running surface water should be redirected and eliminated at any burial site where it is observed. Usually water can be drained away from graves and their headstones and memorials through shallow trenches, though in some cases more significant remedial work (French drains or other) may be required; see the guide section on landscaping on this website for more information. Surface and shallow subsurface water also contributes to sudden and devastating fracture of headstones during the cold months of the year, when saturated stone must endure repeated freeze-thaw cycles; the importance of water management in cemeteries cannot be over-emphasized.

Another environmental stress to headstones which can be partially mitigated through landscaping is the impact of cemetery visitors. In some cases it may be possible to visually indicate preferred walking paths which prompt visitors to keep more than arm’s length distance from standing and fallen headstones, to reduce casual touching, rubbing, and impact at the carved stone surfaces. This approach will not stop all human contact with headstones (and probably should not) but can reduce wear and contamination while better preserving the visual and memorial value of the stones.

Otherwise, the advice to manage vegetation at the cemetery site (which appears repeatedly on this website) remains important as a preventive conservation measure. In addition to reducing the load of organic material (grasses and leaves, especially) adhering to stone surfaces, cutting or extracting large shrubs and trees of all sizes which are rooted next to headstones can quickly eliminate imminent damage from pressure above and below the soil surface.

Cleaning Carved Natural Stone Materials

A volunteer hand-cleans a Jewish headstone at the Bagnówka Jewish cemetery in Białystok, Poland. Photo © Heidi M. Szpek.

Headstones, and especially their inscribed and/or carved faces, may be mechanically and chemically cleaned in order to:

- remove soil and sand, mud and dust, sap from plants and trees, and bird droppings

- remove soot particles and chemically-active deposits from air pollution

- remove biofilms, and kill and remove biological organisms including bacteria, mold, mildew, algae, mosses, and lichen

- retard the regrowth of biological organisms

- reduce salt-driven stone disintegration

- reduce or remove stains, including from dirt and graffiti

- prepare a stone for repairs or other conservation work

Headstones may also be cleaned only to “improve” or change their appearance (although strictly speaking this is not a form of conservation, and may in fact strip the stone of its visual record of history), and in some cases to improve the legibility of epitaph inscriptions.

It is critical that the cleaning process should do no harm to the headstone in the short or long term; stone is a hard material but also a delicate one. Cleaning may appear to be a low-skill task, but the materials and methods must be selected and managed by someone knowledgeable and experienced, and ongoing testing and evaluation of effectiveness and risks in the process is necessary to prevent irreversible damage. It is always wise to use the gentlest (mildest and least abrasive) mechanical and chemical cleaning methods and materials available, to avoid removing or altering the original stone surface.

An important note: Many of the cleaning processes described here use large quantities of water, and for these, ensuring an adequate supply of clear water is the most important preparatory step in the cleaning process. Also, saturated stone may be damaged by freezing weather; headstone cleaning should be scheduled for days when there is no threat of freezing temperatures overnight or for several days after the work. Because acidic solutions can readily dissolve the constituents of some common natural stone materials – especially limestone – water used for wetting, cleaning, and rinsing headstones during cleaning should have a pH which measures neutral to slightly alkaline; this can be verified by testing before beginning work. Water supplied from urban utility piping or unknown sources should also be tested and confirmed to have only low concentrations of salts and impurities known to harm or stain stone, including iron and magnesium.

Headstone cleaning best practices as outlined by the NCPTT and other experts are provided in books, reports, articles and videos listed on the references page for stone conservation on this website. They include:

use plenty of clear water: soak the entire stone liberally before applying any cleaning solution; keep the stone wet during cleaning; rinse liberally after cleaning every section of the stone; thoroughly rinse the stone after cleaning; never let the chemical cleaning solution dry on the stone

use low-pressure water spray: use manually-pumped hand or backpack spray bottles; if mechanical-pressure washers are used, set the pressure to below 3MPa and hold the nozzle at least 30cm from the stone, testing carefully before cleaning

use a suitable chemical cleaning solution: acceptable solutions include non-ionic detergents, surfactants, and solvents, as well as biocides containing quaternary ammonium compounds; use cleaners known to be harmless to stone; avoid salt-based cleaners

Drench the stone liberally with water first, then spray with a compatible cleansing solution.

Source: NCPTT Materials Conservation.

use a pH-neutral chemical cleaning solution (or one matched to the pH of the stone): avoid strong acids (muriatic acid, hydrochloric acid, etc.) – even mildly acidic cleansers which are effective on siliceous stone such as sandstone and granite may harm calcareous stone such as limestone and marble; avoid strong bases (concentrated ammonia, sodium hydroxide, calcium hydroxide, potassium hydroxide)

avoid liquid bleach solutions: sodium hypochlorite (NaClO) and other bleaches leave soluble salt residues leading to long-term stone damage, and can etch stone surfaces upon contact

prepare and use the cleaning solution as prescribed by the manufacturer: chemical cleaners should be diluted in water to the specified strength, applied, and left to dwell on the stone surface only for as long as defined in manufacturers’ instructions

test the cleaning solution before use: apply the chemical solution to a small wetted area away from carved and incised features to establish safety and compatibility before cleaning larger and feature-rich areas

Soft-bristle brushes suitable for cleaning natural stone. Source: NCPTT Materials Conservation.

use soft natural- or synthetic-bristle hand-held brushes: agitate the wet stone surface in a small circular motion by hand; avoid pressing the brush hard against the stone; check continuously for weak areas; avoid metal-bristle brushes and metal-bladed and -tipped tools

avoid mechanical-abrasive tools: do not use sand-blasting machines, motorized sanders, drills or grinders with abrasive attachments

clean from the bottom of each surface up (for upright headstones): work upward to minimize streaking from chemical cleaning solutions

use personal protective equipment plus caution: all volunteers cleaning and/or handling stone, tools, and materials should wear gloves and eye guards or face masks, and have access to water for frequent rinsing of skin and clothing; follow cleaning solution manufacturers’ instructions

Brushing gently in a circular motion from the ground up. Source: NCPTT Materials Conservation.

Although soluble salt residue in stone pores poses a significant threat of surface damage to natural stone materials, ammonium carbonate (itself a mildly base salt) can be helpful when used in compresses or poultices applied to the faces of headstones. This is because ammonium carbonate in solid form decomposes to ammonia and carbon dioxide, both of which are gases at normal environmental temperatures, so a poultice paste including ammonium carbonate can extract other, harmful salts and then leave no solids of its own behind. See the GGI Lectures on Material Science for Architectural Conservation (Giorgio Torraca, 2009, p.99) for more information.

Clean carefully to preserve traces of history, such as the delicate prewar paint still present on this headstone recovered and returned to the Jewish cemetery of Sokolivka. Photo © RJH.

Additional details about many of these topics can be found in an extensive research report published by the NCPTT which evaluated more than 30 cleaning solutions and then chemically and physically tested the 5 best candidates both in the field and in the laboratory. The evaluations considered effectiveness and risks to stone materials in removing mechanical, chemical, and biological contamination, as well as retarding the regrowth of biological organisms. While most of the branded commercial products included in the study are not available in western Ukraine, the chemical cleaner categories and descriptions as well as the detailed advice are directly applicable to stone conservation work in these regional cemeteries.

A novel stone cleaning technique using far less water was developed by art and architecture conservators at Lviv Polytechnic National University (LPNU) in Ukraine, and published in Ukrainian utility patent UA76956U of 2013. In the process, an aqueous solution of polyvinyl acetate (PVA, i.e. common polymeric wood glue, and in a following patent UA93614U from 2014, with the addition of a variable amount of glycerol) is brushed onto the stone surface and when dried creates a film which can be peeled from the stone, removing surface contamination in layers without the need for a reinforcing fabric material. This method uses large macromolecules to limit the subsequent blocking of pores, adheres less strongly to the stone, and avoids the strong acidic components of some related approaches, so is less harmful to both the original and cleaned stone. The method has been successfully tested on stonework at the Tustan medieval rock fortress and national historical-cultural reserve in the Lviv oblast. The method can be adjusted based on the porosity and integrity of the original stone. One caution is that the film should not be left on surfaces to be cleaned for more than a day, as it gradually forms stronger mechanical bonds with the stone. Contact the Department of Restoration of Architecture and Artistic Heritage at LPNU for more information.

An alternate stone surface cleaning technique still in development but already showing promise at heritage sites in Europe and elsewhere employs lasers to selectively and sensitively remove dirt and other contaminants. The method uses no water or solvents and requires no contact between the tools and the delicate stone surface, so it avoids many of the inherent risks of the methods described above as well as the problems associated with waste water and chemicals. However, laser cleaning has risks of its own (both to the stone and to the users), and requires specialized training and experience to safely use; it is also expensive and somewhat difficult to use at remote sites such as rural cemeteries. See the references on stone conservation on this website for more information and case studies about this alternative cleaning approach.

In every cleaning project, it is important to document the stone before, during, and after the cleaning. Photos © TheUrbanPrepper.

Stone Consolidation and Protection

A volunteer treats a Jewish headstone with a sealant at the Bagnówka Jewish cemetery in Białystok, Poland. Photo © Heidi M. Szpek.

Heritage stone exposed to the natural environment decays over time and especially under the influence of water. Decay manifests several ways; most significantly for the aesthetic and documentary value of a headstone it is the (usually) gradual loss of carved surfaces presenting the epitaph and often the sculpted symbolic elements which carry historical meaning. Surface decay of stone results in a loss of material cohesion, weakening against further decay, and failure of surface adhesion to the deeper stone core; stone conservators refer to this weakened stone as disintegrated, friable, or incoherent. Conservation of historical buildings may allow the replacement of decayed stone with new matching material, but replacement is almost never a reasonable option for headstone conservation. Consolidation and strengthening of degraded stone surfaces to slow further decay and the complete loss of carved surfaces is desirable, but as explained here is rarely practical in historical Jewish cemeteries.

For two centuries and increasingly in recent decades, stone art and architecture conservators have experimented with a variety of consolidation treatments, most of which involve a penetrating liquid that fills small voids near the stone surface, then solidifies through solvent evaporation or chemical reaction to replace lost inter-granular cement and help recover some of the lost material strength of the original stone, converting an outer layer of limited depth into a composite. No consolidant treatment can comprehensively meet the needs of a preservation project, especially for an indefinite time period and while also affording reversibility for when better methods become available in the future. Consolidant materials must be chosen and applied carefully, on a case by case basis with regard to the specific stone type(s) and the site conditions; this is a task best left to expert stone conservators with local knowledge and long-term experience. At most, one can hope for a reduction in the future rate of decay for a period of time – not a cure for past or future problems, and certainly not forever.

An idealized graphic showing decayed stone before and after application of a consolidant penetrating from the left face. Source: Historic England.

The vast majority of scientific literature on stone consolidation and water protection is focused on building and monument elements without earth contact; rainfall and wind plus the secondary effects of soluble salts are the primary erosion agents. Clear and detailed explanations of the materials, processes, and past results in this field are published in a series of lectures with advice on the relevant materials science (Torraca; see the references page on monument design and repair on this website), as well as a broad review of available research as of 2010 (Doehne and Price), plus an earlier comprehensive text (Ashurst and Dimes; see the references page on the care of stone). The stone references page also includes links to a large number of other digital and print books and scientific papers on methods and materials for stone consolidation and protection by impregnation. In this brief section we have distilled a summary with remarks about the special challenges of applying these treatments in cemetery preservation.

Testing various treatments to control salt damage to limestone under accelerated conditions. Source: NCPTT and Princeton University .

Even for the exterior stone surfaces of buildings, past research and case study reviews give a very pessimistic view of the effectiveness of consolidation treatments. Accounting for the short-term benefits, unwanted side effects, long-term detrimental effects, and the lack of reversibility of many treatment options, cemetery preservation projects will often choose to abstain from intentional treatments in order not to undertake ineffective or even harmful work. Water repellents have a record of even worse performance: one broad review of dozens of individual treatments on several stone types showed decay rates were not changed or were made worse at more than 90% of sites, and many also suffered additional appearance problems. The caution given above on this page to precede any cleaning procedures by documenting the headstone carefully (see the documentation guidance below) is even more important before attempting any surface treatment; in many cases that documentation alone is probably the best effort a project can make for a given stone.

However, some general guidance can be taken from the academic literature, as summarized here:

-

Soft granular decay of stone behind hard, brittle crusts. Source: Historic England.

consolidation is only effective on surfaces exhibiting granular disintegration, i.e. which shed very small grains of stone (not more than a few millimeters in size) under light pressure or scratching; where there are easily-visible cracks, larger flakes, or layer separation, a micro-filling or adhesive process is usually a better-suited repair;

- the specific type of consolidant should be matched to the specific type of stone, and the performance of individual consolidants cannot normally be predicted from simplistic designations of stone type as are used here, e.g. limestone vs. sandstone;

- some successes have been reported on limestones with lime water (as a consolidant, a putty, and a shelter coat), with epoxy resins, and with acrylic monomers (though this is difficult to effectively apply in the field);

- some successes have been reported on sandstones with ethyl silicates (though not easily applied in the field), as well as silanes and siloxanes (though these are not generally reversible, so are often prohibited by conservators);

- moisture control in the stone is important throughout the treatment, especially for water repellents; most applications require fully-dry stone, others benefit from pre-wetting to depth and controlled drying at the surface to limit the depth of consolidant penetration;

- consolidants which form hard and brittle composite surface layers may fail quickly and massively if they do not penetrate fully to a solid stone core, or if the composite coefficient of thermal expansion is poorly matched to the core stone;

- consolidants based on organic components tend to oxidize in exposure to the environment, and while they can be more flexible than other treatments they tend to be less durable (requiring more frequent treatment);

- success in the use of consolidants and water repellents is significantly lower in outdoor applications (especially the “hostile ambient conditions” typical of a cemetery) when compared to controlled application environments, e.g. in museums; it is often difficult to carefully control treatments in the field;

- rising damp in buildings commonly negates the beneficial effects of wall treatments in those applications; this points to a fundamental issue in treating traditional Jewish headstones in western Ukraine (see below); and

- while some approaches to stone consolidation are more than a century old and are still in occasional use (with well-known limitations and side effects), modern materials and methods become outdated quickly as time reveals their inherent flaws and as newer formulations and processes are developed; a cemetery should not become a laboratory for experimentation.

A silane-based water repellent coating in use on stacked monuments at a Magurycz-led cemetery project in Poland. Photo © RJH.

A fundamental issue which must be considered prior to treatment of surviving Jewish headstones in western Ukraine is the benefit – or risk – of “waterproofing” the stone surface, which may occur either through the application of a consolidant or a secondary water repellent. Most Jewish headstones which still stand at their original grave locations are embedded in packed earth (i.e. ground-supported), naturally wicking water up from the soil. In a headstone which is not “sealed” this water can migrate through the stone and evaporate from its faces. Stones which are not ground-supported (e.g. stacked headstone assemblies such as are found in many historical Christian cemeteries in the region, some postwar memorial monuments, plus Jewish headstone fragments recovered from misuse as building materials and reused in memorials without soil contact) are not inherently at risk from groundwater (though they still can absorb rainwater and snowmelt). For this reason, some Christian cemetery restoration projects intentionally introduce an impermeable synthetic barrier between the stone markers and the ground, an option not available to projects in Jewish cemeteries.

Although there are hypothetical benefits to repelling water at the stone surface, conservators generally believe that stone needs to “breathe”, and there is a long history of poor results after using water repellents on porous stone such as the limestone and sandstone which are most common in Jewish cemeteries in western Ukraine. Perhaps an ideal combination would be a composite layer which transfers water vapor but not liquid water, but we are not aware of a commercially-available coating for porous stone which marries these qualities (one reference suggests treatments which form silicone coatings, e.g. silanes, may retain half of the original permeability of stone to water vapor, while blocking liquid water). This question/issue is also relevant to coatings applied to Jewish headstones for other reasons, e.g. decorative paints which enhance the legibility of epitaphs or restore original coloring (polychrome has historical precedent in Galician Jewish cemeteries), or to enable easier removal of graffiti.

Headstone Repair

Repairing broken headstones by reattaching fragments is not a common project activity in regional Jewish cemeteries. Most often, headstones are found broken and the loose pieces are separated and lost, so no repair is possible. Because headstones were often “harvested” from Jewish cemeteries for misuse as building material during or after World War II by breaking the stones into two or more pieces, contemporary recovery projects such as the case studies linked above usually find only fragments (half or less of each original stone) scattered around a town, and searches for near-complete stones or matching fragments are rarely successful. Nonetheless for some projects a small number of headstones are discovered broken in the cemetery or elsewhere and with most or all original pieces together.

Stone repair is best managed by experienced stone conservators familiar with the specific materials, environments, and issues related to Jewish cemeteries in western Ukraine. Skilled stone masons can manage this work if they have studied the issues and have a track record of repairing similar heritage natural stone monuments. Cemetery project leaders who are considering the repair of one or more headstones will benefit from reviewing the resources on the references page for stone conservation and for memorial monuments on this website. Anyone who considers this type of repair “simple” can learn from reviewing a pictorial overview of the materials and methods (from a project on marble headstones in a North American Christian cemetery) and especially a few of the many caveats published by experienced practitioners and academics on the topic. Here we provide an introduction to the topic, but strongly defer investigating, planning, and conducting the project work to experts.

Nearly all Jewish headstones in western Ukraine are monolithic stone slabs (also called tablets or steles) in style, cut and carved from limestone or sandstone, and are (or were) set upright with a portion of the base embedded in earth (ground-supported, i.e. without a separate base), so the repair guidance here is tailored to those styles and materials. The much less common examples of grave covers (similar to ledger stones), stacked stone markers built onto bases, and “boot” styles, as well as composite concrete/brick grave marker and surround materials, are not addressed here, but repairs for most of those can be considered using resources on the monuments references page on this website.

Headstones recently chipped, broken, and toppled by woodcutting in the new Jewish cemetery of Vyshnivets (Ternopil oblast). Photos © RJH.

For repairs (as for other heritage stone work) the usual conservation guidance applies:

- document the stone before and after the attempted repair;

- do not make purely “cosmetic” repairs, i.e. where the stone is not at risk of accelerated decay or damage;

- do no harm (or as little as possible) to the original stone materials and historical carved surfaces;

- use chemically-, mechanically-, and thermally-compatible repair materials;

- make repairs as invisible as possible (tight and neat adhesive joints, color-matched mortars, no excess adhesive left on visible faces, no face pinning or cramping); and

- make repairs which are reversible, wherever possible.

A wide variety of adhesives are available for natural stone repair, usually divided between a broad category of mortars blended specially for repair work on specific types of stone vs. structural adhesive thermoplastic or thermoset resins which provide greater joint strength (typically with side effects which must be managed). The choice of adhesive normally depends on the type and magnitude of stress the repaired joint will have to bear in the future, the condition of the stone at the fracture faces, and the size of the gap between those faces. Many types of stone adhesives are evaluated by process and performance in numerous books and articles on the stone references page on this website; an especially good guide to selection of repair mortars based on the toughness of stone (most heritage headstones are “moderately” tough), the condition of the stone at the fracture face (from “good” to “poor” for headstones, normally depending on the age of the break), and the environmental exposure (cemeteries normally categorize as “moderate” to “very exposed”) is given in an appendix to the English Heritage guide to practical conservation of stone. Careful conservation practice aims to make mortar joints weaker than the original stone so that if a joint is overstressed the mortar will break instead of the stone. In practice this means that repair mortars are normally softer lime-based materials. Binders composed of harder Portland cement are almost never used (despite the ubiquity of Portland cement at materials suppliers) because of the material’s relatively high stiffness and strength, its significant impermeability to water, and its relatively high thermal expansion coefficient, as well as its chemical incompatibility with natural stone (e.g. the tendency for Portland cement to produce soluble salts as it sets).

Regional stone masons and conservators are familiar with the long-term performance of available structural epoxies and acrylic resins (e.g. Paraloid B-72, which is reversible by solvents but may lack longevity in outdoor exposure) for stone work. A detailed overview of the chemistry, performance, and risks in using natural and synthetic polymers in stone conservation work is provided in the GCI text on materials science. Unlike most mortars, typical stone adhesive resins have low permeability to moisture, which can create a water barrier at the repair joint and cause accumulation of soluble salts on one or both sides of a repair, though it is not yet known whether this creates a long-term risk. Mortars and resins which must bridge across large gaps can be modified with fillers including pulverized natural stone, as in conventional stone masonry work.

Before repairing/re-attaching even a recent stone fracture, the fracture faces should be cleaned and prepared to receive and bond with the adhesive. For standing headstones, it is generally best to reset the ground-supported portion of the stone upright before the repair (see below), if it is tilted more than a degree or two, as progressive leaning or a future resetting operation may over-stress the joint; this is especially true if the intended joint is in the lower half of the stone (i.e. a significant portion of the repaired headstone will be above the repair joint). Biological organisms (mold, lichen, etc.), surface salts, and friable stone (crumbs and dust) should be removed from the fracture faces regardless of the adhesive type intended to be used; loose material in the joint is a common cause of joint failure. Importantly, the original stone should be dried on both sides of the joint to a depth well beyond the fracture faces; in practice this requires either several continuous days of warm and dry weather (rare in western Ukraine) or a concentrated source of external heat applied over several hours.

Brief guidance is given here for several categories of repair, but as noted all of this work should only be attempted by trained conservators or stone masons with experience in working with heritage natural stone in cemeteries:

hairline cracks, blisters, and voids: If visible cracks are deemed likely to grow and lead to further damage, or loss of the documentary or aesthetic value of significant portions of a headstone, non-structural micro-filling with grout or resins may be needed. Fine cracks, blisters, and voids can be filled either through gravity or injection (using syringes made for building work or for veterinary purposes), provided the space between separated stone surfaces is accessible and can be cleaned. Mortars typically must be sifted to remove larger granules and mixed to a thin, low-viscosity consistency (as grout); resins should also be mixed thin to enhance penetration. See the GCI materials science lectures and the Ashurst stone conservation text for further information, and Henry pp.199~205 for guidance specific to small-scale sandstone failures. These repair methods may also be useful where spalling (exfoliation) has occurred and the loose pieces have been retained.

A Jewish headstone made of sandstone found delaminated into three layers during recovery work

on Barvinok Street in Lviv. Photo © RJH.

delamination (layer splitting or exfoliation): Cut sandstones are prone to separation into slices a few or many centimeters thick at bedding and lamination planes due to relatively weak adhesion at those interfaces. Separation can be driven by moisture and soluble salt ingress wicked into standing ground-supported headstones, and by lateral forces causing shear and tensile stresses in headstones misused as building materials (see case study 13 and the page on physical properties of stone on this website). Some architectural stone conservators (Henry pp.202~203 and English Heritage p.229) have proposed injected acrylic or lime-based (reversible) adhesive with face-pinning for reinforcement, an approach which is not advised for grave markers because of the resulting permanent disfigurement of carved faces. An alternative approach also using reversible adhesive at the separated faces instead clamps the side faces of the reassembled stone within non-ferrous metal channels and elastomeric pads; this approach is visually unattractive but does not permanently alter the appearance of the stone.

larger open cracks and missing small block fragments: Infill of open crack edges and bridging open areas missing from headstones is generally not advised unless the unmodified stone would likely suffer accelerated decay at the exposed surfaces. Replacements and additions will significantly alter the appearance of a headstone in ways which are not sympathetic to the marker’s history and age. Conservators (Henry p.178 and others) recommend lime grout or fine lime mortar, or any moisture-permeable material compatible with the natural stone which can be removed as needed in the future. Material should be added only to protect vulnerable surfaces, not to recreate the missing parts. In rare cases, the addition of an uncarved “Dutchman” stone of the same natural material as the original to replace a missing original piece may add structural integrity to a broken headstone at risk, at some visual cost.

Broken blocks of a stone grave marker are reassembled and bonded with epoxy, straps, and clamps by the Magurycz team. Photos © RJH.

detached small block fragments: Smaller fragments of headstones broken loose from the main stone can often be re-attached (i.e. adhered in place) without added reinforcement. If the fracture faces can be closely mated without a significant gap, stone epoxies can achieve a strong bond by themselves, even when the cured bond must bear shear stress. If the fracture faces are partially disintegrated or the joint gap is large, and the joint will be stressed only in compression, in most cases the repair can use filled lime mortar or grout as the adhesive. Smaller fragments with joint loading in shear will typically require some form of reinforcement (wire or pins), as for larger fragments (below).

The Magurycz team assembles and bonds a stacked stone grave marker with mortar in a cemetery in southeastern Poland. Photos © RJH.

detached large block fragments: Larger loose blocks of stone are reattached in the same way as smaller blocks, but usually require some form of joint reinforcement to spread the post-repair stress loads over a larger area. In the softer stones from which historical headstones in western Ukraine were typically made, hidden or “blind” pins (also called rods or dowels) of a diameter 10% to 20% of the thickness of the headstone and 10cm to 20cm in length are used. Because of long-term weather exposure, the pin material must be highly resistant to corrosion – stainless steel (often type 316), titanium, phosphor bronze, glass-fiber reinforced epoxy, and carbon-fiber composites are good; plain and galvanized steels are not. To ensure a good bond between the adhesive and the pin, many pins for stone repair have textured, knurled, wound, or threaded outer surfaces. The stiffness and strength of pins can be a problem if their coefficient of thermal expansion is significantly mismatched to limestone or sandstone; titanium pins are preferred over many other materials for this reason. If there is a significant risk of high joint stress after the repair, some conservators recommend using lime mortar adhesives with pin materials which are weaker than the stone at the joint, including glass-fiber reinforced epoxy or even wood, so that damage resulting from high stress is limited to the adhesive and the pins rather than the original stone.

Sometimes simple dowels, straps, and gravity are sufficient to stabilize a stone fracture repair during adhesive cure. Photo © RJH.

Aligning detached fragments adhered with or without reinforcement may be possible simply by mating the parts at the fracture faces, if the break occurred recently and the stone material has not significantly crumbled. If no close registration is possible at the joint, a bench or concrete pad covered with a plastic sheet can provide a flat surface for ensuring coplanarity of recovered fragments during adhesion, with blocks to provide a perpendicular reference plane for lateral alignment; for standing stones, temporary reference planes can be improvised with angle-section steel and/or lumber. Temporary clamps and/or ratchet straps can hold the parts tight and stable during the adhesive cure if gravity alone is not sufficient. A US-based cemetery conservators’ website illustrates a variety of support and clamping methods for heritage marble grave markers; the materials and dimensions are not typical of Jewish headstones in western Ukraine but the procedures are helpful.

Depending on size, material, and finish, pins range in cost from less than US$1 to about US$30 per piece. The type, number, and size of blind pins appropriate for reinforced repairs should be evaluated individually for each headstone and damage situation. Larger pins spread stress over larger areas of stone, but sacrifice more original material within the stone during drilling. Pins should normally be placed two or more diameters from headstone faces (one reference suggests six diameters) to minimize the risk of shattering the stone. Masonry drill bits should be carbide- or diamond-tipped, driven by a variable-speed non-percussive drill motor. Alignment of the paired holes on each side of the joint face is critical, to avoid contact stress and to minimize the thickness of adhesive, which is important especially in epoxy bonding. Clearing out the drilled holes is as important as cleaning the fracture faces, to ensure a good bond between the pins and the stone. A good diagram of the overall pinning procedure is published in the English Heritage guide to practical conservation of stone p.230; additional figures for a variety of reinforcement situations are given in the Historic Scotland guide to conservation of historic graveyards pp.54-55; both guides are listed on the stone conservation references page. A detailed evaluation of the engineering performance of pinned sandstone repairs is given in an MS thesis by Marco J. Federico for UPenn.

Headstone Resetting

Volunteers hoist a Jewish headstone for resetting at the Bagnówka Jewish cemetery in Białystok, Poland. Photo © Heidi M. Szpek.

Undamaged monolithic headstones in Jewish cemeteries in western Ukraine are often tilted out of plumb (vertical) or have fallen due to settling or instability of the soil which supports the stone. Soil subsidence may have been caused by the original excavation and refilling of the grave, meaning the tilt seen today may have begun within a few years after the headstone was originally set. Other causes of instability are nearby tree growth (in particular the root structure) and water management issues; these problems should be corrected to stop progressive damage. Slab headstones which are deep-rooted, with as much as a third of their height buried in now-compact soil, may remain tilted even at significant angles for decades or more, so likely need not be reset, and in fact resetting loosens soil again and may cause new problems, if not carefully performed.

However, resetting headstones is sometimes appropriate in regional Jewish cemeteries, either to upright severely tilted stones so they can be read, to erect stones which have fallen in place in the cemetery, and to create new memorials using headstones recovered from outside the cemetery. Some of the methods described in this section are also useful for working with subsided memorials composed of several separate stones. As for all of the repair and conservation procedures described on this page, the work should only be undertaken by skilled and experienced practitioners, in this case familiar with both historical natural stone and the means to safely move heavy objects.

Academic texts on stone conservation typically focus on buildings and monuments and do not address headstone resetting; Henry (p.301, 311, 314~316) is an exception. Practical articles and videos produced by the NCPTT and several cemetery conservation organizations (see the references page on stone care on this website) provide valuable visual and text guides to safe and effective tools and methods. The Polish NGO Stowarzyszenie Magurycz has been resetting grave markers of all types at cemeteries in central Europe for decades, and conducts hands-on work camps to demonstrate methods and train volunteers while conserving several cemeteries each year.

Large Jewish headstones standing in Rohatyn in the 1930s and in Brody a few years ago. Photos © YIVO and Tammy Hepps.

Although delicate, historical Jewish headstones in western Ukraine are extremely heavy; intact ordinary stones weigh several hundred kilograms each, and the largest surviving headstones in the region easily weigh more than a metric ton. Any attempt to reset a Jewish headstone in regional cemeteries requires heavy-duty manual or powered equipment, related skills and experience, and many hands, plus an abundance of caution. Because resetting usually requires some excavation, rabbinical advice and supervision is almost always appropriate.

Before commencing work, the headstone to be reset may need to be protected from the equipment which will move it, including straps and other supports which create high contact pressure. Plywood or similar panels padded with cloth or foamed plastics can be built to protect faces and edges; these protection features must themselves be very strong. Headstones which are cracked may need extra bracing, or if parts appear loose they may need to be removed before starting the resetting.

Straps used to support and lift the headstone should be without defects and sized to easily bear the full weight of the stone. The stone should be fully supported before any excavation work on the supporting soil begins, to avoid jerking the straps or sudden collapse of the stone. The stone can be lifted using a chain hoist or other compound lifting device (e.g. a winch or block and tackle) with a ratchet or locking mechanism. Typically the hoist is supported on a high and well-anchored tripod or gantry to permit small lateral movements as needed for the reset. If the cemetery grounds can support heavier powered hydraulic equipment, multi-axis lifting and placement is possible. Several articles and videos demonstrating stone-lifting tools and procedures are listed among the references on this website; an NCPTT article and an associated video specifically on safely using hoists for lifting headstones are both very good, and internet browser searches will return other useful articles and videos.

For ground-supported headstones, a typical resetting procedure is demonstrated in an NCPTT video which is particularly clear and helpful even though showing relatively small headstones. Website pages written by other cemetery conservators also illustrate the process and some cautions. The process sequence overall is:

-

Jewish headstones reset with gravel and sand at the new cemetery in Brody (Lviv oblast).

Photo CC-BY-NC-ND Christian Herrmann.support the headstone with straps and the hoist

- dig carefully around the base of the headstone to loosen the soil in its immediate vicinity, until the headstone is loose

- lift the headstone just above ground level and move it clear of the hole, if possible

- adjust the hole depth with a shovel (it may need to be higher or lower to accommodate new materials), removing tree roots and large stones in the process

- tamp the soil to compact it, adding more soil and tamping as needed to maintain the prescribed depth

- add a 10~15cm layer of sharp (not rounded from stream- or river-washing) medium-sized gravel to the hole, and tamp it again

- replace the headstone onto the gravel in the hole, using a post level to adjust it plumb while restraining the stone with straps and/or wooden bracing

- add another 10~15cm layer of sharp medium-sized gravel to the hole, and tamp it again (with a wooden post or board to avoid metal contact with the stone)

- add original soil and/or sand in layers, tamping each layer and using a small amount of water to help compact the soil, until the new surface around the headstone is slightly higher than the original level

- remove the level and straps or braces, then wash the headstone to remove soil and marks left from the resetting process

The Magurycz team using a timber hoist to disassemble and reassemble stacked grave markers in a cemetery in southeastern Poland. Photos © RJH.

This recovered headstone at the Jewish cemetery in Sokolivka has ample root depth for resetting. Photo © RJH.

Common guidance on set depth for ground-supported headstones calls for at least one-third of the overall height of the stone to be embedded in compacted soil, to provide adequate resistance to overturning moments over the long term. If a headstone is broken near the base (which is common on recovered headstones) or otherwise has a “root” too short below the inscription to give the desired support, it may be appropriate to affix the headstone in a separate slotted (socket) base which is placed on or in the earth at a shallow depth. This installation technique was not common for original headstone placements in western Ukraine until the 20th century, but it can be a useful approach now with damaged headstones.

A small headstone reset into a precast concrete base with gravel and soil in the Jewish cemetery of Oświęcim, Poland. Photo © RJH.

Ideally a new slotted base is cut (by a stone mason) from natural stone of the same type as the headstone, with a slot area slightly larger than the headstone cross section and a slot depth of 5cm to 20cm (at least equal to the thickness of the headstone), though it is possible to use a precast concrete base similarly spaced from the headstone. If there is very little available length of headstone below the inscription, the joint between the headstone and the base can be strengthened with blind pins as described in the repair section above; this approach can also be used on a flush base (without a slot), as shown in the Historic Scotland guide to conservation of historic graveyards.

The base must be placed level on flat compacted soil, and may be inset nearly flush with the soil surface by excavating slightly followed by tamping the soil. The headstone is then cleaned and bedded with spacers in lime mortar – not Portland mortar or concrete – in the base slot, with the mortar collar finished slightly higher than the base and beveled away from the headstone to shed water. The headstone hoisting and bracing procedure for slotted bases is as described above for ground-supported headstones. The references page for stone conservation lists several articles with information about slotted-base setting, including a detailed article by Cemetery Conservators for United Standards, and an NCPTT video on resetting stacked bases with pins which can be adapted for a slotted base.

Casting a new concrete slotted base onsite and resetting a headstone in lime mortar in the slot.

Stills from a cemetery preservation conference presentation by Jonathan Appell and published by the NCPTT.

Documenting Headstones

A field school conducted by Jewish Galicia and Bukovina to document matzevot in a Jewish cemetery in the region. Click the image to see the video.

Even the most active conservation efforts will not stop the gradual erosion and disintegration of carved lettering and symbols on the surfaces of natural stone matzevot in Jewish cemeteries due to weathering and other factors. At best, skilled material conservation can slow the decay, while mistakes in cleanings and repairs, though made with good intentions, may ultimately accelerate the loss of stone features and with them the legibility of epitaphs and the artistic legacy. Conservation of Jewish headstones as records of past individuals and communities, and the culture they developed and passed on, thus depends on intangible preservation of some aspects of these material objects in the form of documentation.

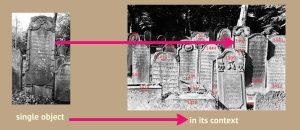

Methods for measuring and recording the locations of headstones within a cemetery are described in the guide page to site surveys on this website, and the print and digital references page on surveys provides a number of links to resources for documenting quantitative and qualitative data about historical grave markers in cemeteries. The same guide and reference pages also give several approaches for interpreting the inscriptions and carvings unique to Jewish headstones, and two different practical examples from western Ukraine are summarized in case study 02 and case study 04 on this website as well (for Ukrainian-language readers, the activist of case study 04 has provided a very helpful introduction to this topic in an interview for the Zbruč online journal). Among the listed survey references are several articles and videos on 3D scanning, reflectance transformation imaging, and photogrammetry as methods to capture detailed three-dimensional representations of headstone faces or entire stones as alternatives and extensions to traditional still photography documentation. The next years will undoubtedly bring more and better techniques to record, analyze, and visualize matzevot at points in time before their physical data is lost.

Contextual linking in the epidat database of Jewish headstone inscriptions;

click on the image to link to the overview.

Attention then must be paid to preservation of the recorded headstone information in its various formats. Copies of digital records including documents, photographs, and video should be described and archived in systems designed for long-term storage such as the Internet Archive. Organizing, labeling, and indexing of the data is particularly important for searching and discoverability. The study of headstone inscriptions and carvings relates to epigraphy, semiotics, and art history, and may benefit from categorization and description tools used in those fields as an aid for researchers sharing data and analysis. The EpiDoc encoding scheme may be useful for some deep documentation efforts, and has already been integrated with the large “epidat” database project of the Salomon Ludwig Steinheim Institute for German-Jewish Studies (see this 2013 presentation on its use for Jewish cemetery funeral inscriptions and headstones).

Important Considerations and Cautions

Surviving Jewish headstones are so rare in western Ukraine that finding one (here, in the new cemetery of Krakovets) can be an emotional experience. Photo © RJH.

Conservation of Jewish headstones in western Ukraine is a very large and complex topic, impossible to distill into a single webpage, and as noted above the majority of the work is almost always best left to trained experts. Reading this webpage in parallel with using the print, digital, and video resources listed on the stone references page on this website (especially some of the brief illustrated overviews produced by the NCPTT and other institutions) can give a good introduction to the field even for cemetery project leaders who do not plan to conduct stone conservation work with their own hands. Hopefully it is clear that directly adapting textbooks and academic journal articles without in-person expert training, or adapting materials and techniques from modern building construction, is rarely advisable. Key considerations already mentioned in the sections above but which deserve emphasis include:

- For most of the centuries before World War II, graves in Jewish cemeteries in western Ukraine were marked by carved natural stone markers from local quarries and set into soil with no foundation, no protection from the environment, and no subsequent conservation, so that the stones decayed naturally over time. Probably for many cemeteries the best approach to preservation is to “curate” headstone decay as a natural process rather than attempt to retard or stop it.

-

Tilted headstones in the old Jewish cemetery in Lviv ca. 1925. Source: CJA

Headstones seen tilting in Jewish cemeteries today are often in that state due to soil subsidence resulting from the original burial process (excavation and refilling the graves). Thus, in many cases tilting is neither a new phenomenon nor a sign of neglect. Further, ground-supported headstones with deep “roots” can tolerate significant tilt indefinitely without overturning or collapse, so remedial action, when it is even necessary, should never be rushed.

- “Preventive” conservation may be the most important action, and often should be the first approach to protecting cemetery stonework from damage or rapid decay. Trimming and removing wild vegetation, managing water flow, setting and indicating paths for visitors, removing impact threats to headstones, etc. are significantly beneficial preservation activities which do not even require touching the stones with hands let alone with tools or chemicals.

-

Documenting headstones is an important element of cemetery preservation. See case study 04 for a thorough project at the new Jewish cemetery of Zbarazh shown here. Photo © RJH.

Documenting headstones is one of the best ways to “preserve” the documentary and aesthetic value of each individual grave marker and of the cemetery as a whole. No headstone conservation intervention should proceed without documenting the stone both before and after the treatment – and in many cases the documentation alone is all that should be done.

- Almost every lay person who believes they know from what material an individual headstone is made and how that material will behave is wrong, in part or entirely. The simplistic categories used here to describe stone properties and responses to treatments cannot capture the many variants within a category or even within a historical quarry, let alone as a result of aging in the specific environment the stone has experienced since it was originally cut. Skilled stone conservation requires experience with these stone varieties as well sensitive observation of both appearance (color, granularity, cracking) and response to stimulus (water, scratching, etc.). Cautious observation and humility are important conservation tools, as we ourselves have repeatedly learned.

-

Some of the many material conservation challenges in the new Jewish cemetery of Shumsk (Ternopil oblast). Photo © RJH.

Aggressive cleaning by mechanical and/or chemical methods can quickly lead to permanent damage of a headstone, reducing its potential life as a memorial object. Absent long-term testing of high-tech cleaning approaches, the gentle application of water is the single most important component of a cleaning program. Metal-tipped tools of any kind and motor power should not be used.

- The unique installation and environmental exposure of historical headstones in Jewish cemeteries in western Ukraine makes many of the treatments developed for the majority focus of academic stone conservation (buildings and monuments) unsuitable and potentially damaging. Any proposed treatment or repair of ground-supported Jewish headstones should carefully consider the effects of that intervention on the flow of ground and atmospheric moisture within the stone.

- When planning a headstone repair or resetting project, it is tempting to aim for a final state which is “better” than the original: stronger, using modern materials. Except in rare cases where the original design or material was actually defective, the longevity of the repair and the stone itself is usually enhanced by matching repair materials and methods to time-tested traditions.

- No cleaning, repair, or resetting lasts forever; especially for mechanical alterations, project leads should consider how the alteration itself will change over time, and design in features to reduce damage to the original stone as that decay occurs.

- Portland cement and the mortars and concrete made from it are useful and versatile in new construction, but are almost universally incompatible in contact with historic natural stone. Stone conservators have developed alternatives (most of which are based on traditional masonry materials) which should be used instead, in any situation where contact with natural stone is required.

Concrete causing damage to natural stone in settings from before WWII in the Jewish cemetery of Rozhniativ and more recently at a cemetery in the US. Photos © RJH and Jonathan Appell via the NCPTT.

This last point deserves elaboration for historic Jewish cemeteries and for new memorials using heritage natural stone markers (headstones or their fragments). Numerous stone conservators, both with academic backgrounds and with extensive field experience, have written on this topic (Henry p.165~167, 195~196; Torraca p.69~71; Odgers and Henry p.17, 80, 158, 233, 290; Ashurst vol.2 p.191; Appell web page; Chicora webpage; Cemetery Conservators for United Standards webpage; Maxwell et al. p.60; Odgers et al. p.16; Anson-Cartwright p.21), and on the NCPTT website one can find considerable related technology development and reporting plus even a graphical essay and a video lecture on the topic. The clear consensus is that while specific repair and resetting requirements vary somewhat, Portland cement and its derivatives are mechanically and chemically incompatible with limestone, sandstone, and other natural stones which were common historical source materials for Jewish headstones in western Ukraine.

Some modifications using concrete can damage without even helping. Photo © Jonathan Appell via the NCPTT.

Mortars and concrete derived from Portland cement (and especially the neat cement used by itself) typically have significantly greater hardness and compressive strength than natural stone, often causing the original stone to break instead of new joining material when joints are stressed; they expel soluble salts as part of their curing process which contaminate porous natural stone in contact, leading to salt-crystal expansion damage; they have low porosity and are relatively impermeable to moisture movement; and they typically have higher coefficients of thermal expansion than natural stone and can induce repeated stress cycles at interfaces in daily and seasonal environmental temperature variation. For all of these reasons, consult with trained natural stone conservators before considering the use of Portland cement or other hard cements as part of any Jewish cemetery preservation project which incorporates heritage stone, especially those which encapsulate the stone, as in a “puddled” wet concrete base poured around a standing headstone in a resetting project, or a concrete wall fixing headstone fragments into a memorial.